Chevrolet Silverado 2007-2013: Transmission Problems and Diagnostics

A lot can go wrong with an automatic transmission. But understanding what could be wrong and then determining what would be involved to get it repaired (or if it even makes sense to try to get it repaired instead of swapping it out for a re-manufactured transmission), is what this article is all about.

This article applies to the Chevrolet Silverado GMT900 (2007-2013).

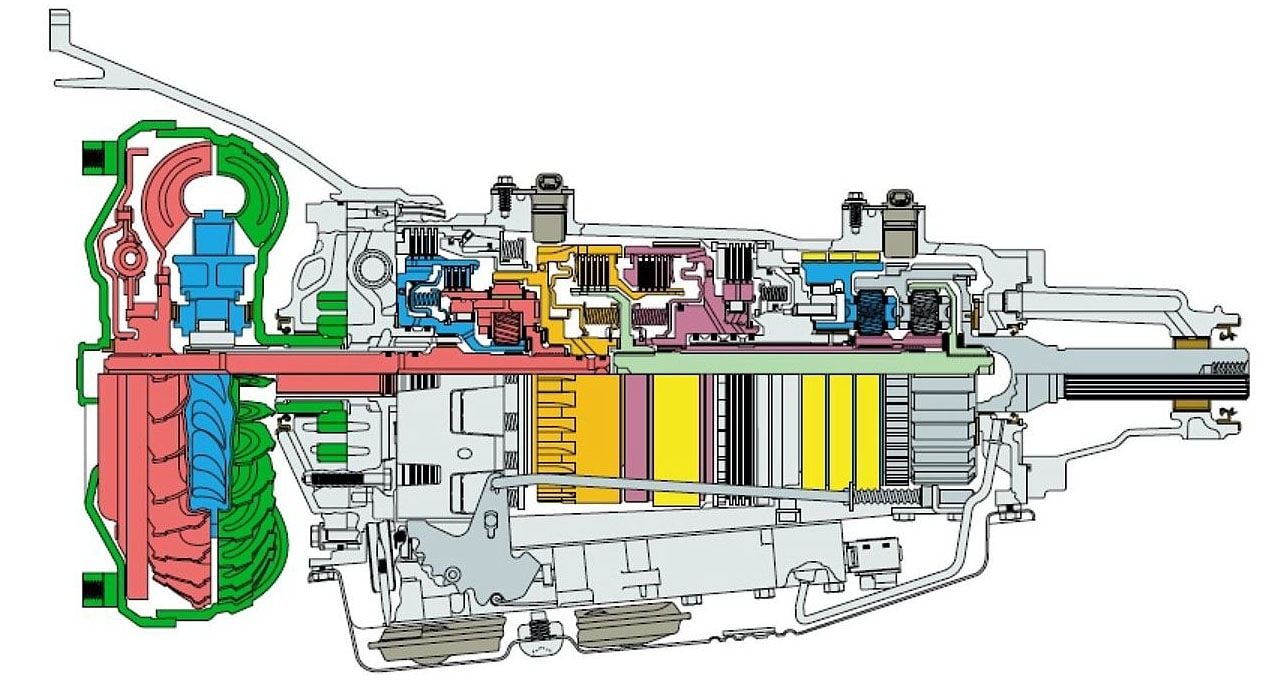

The electronically-controlled “E” version of GM’s venerable 4L60-E automatic transmission was first released in 1992, and within a year it saw widespread incorporation across many GM RWD models. It was used in automobiles from cars (including the C4, C5 and early C6 Corvettes) to pickup trucks, and from 2WD to 4WD.

Over the years, this transmission has seen numerous revisions, changes, and additions to internal components—such as valve bodies, solenoids, pump, and torque converter. In 1997, the “late” model of this transmission that included a removable bell housing was widely introduced. Incorporating a “beefing up” modification in 2002, this transmission is in widespread use today. Most automotive experts would agree that this 4L60-E transmission is the best rendition of one of the best overdrive automatic transmissions ever manufactured.

But as with all machines, due to use and/or abuse, there will be failure. Some transmission failures are treatable, but many others are not because of both the close tolerances and the interdependencies of the many components contained within the transmission housing.

Materials Needed

- OBD-II scan tool

Step 1 – Check for gear selection abnormalities

If you are experiencing strange or abnormal behavior during your vehicle’s shifting operations, the following list could be helpful for tracking down what the problem might be. Note that this list represents both common problems as well as common causes; however, virtually every transmission problem can be brought about by multiple, domino effect-like issues, which are often best investigated with a scan tool.

Pro Tip

Take note of the lowest OBD-II transmission diagnostic trouble code numbers first, as they will typically represent root causes. Higher numbers often represent collateral fault conditions.

Always check first the transmission fluid level and condition to make sure that isn’t your problem.

No movement in any gear (total loss of transmission fluid, or pump failure):

- Refill the pan with fluid and look for a leak. If you find one, fix it.

- For pump failure, check the fluid level with the engine off, then start the engine and recheck. If the level doesn’t go down when the engine is running, the pump has failed.

Partial or full loss of movement (with fluid leaking out of front where torque converter connects):

- Front pump bushing has “walked” out.

- Transmission must be removed and rebuilt.

No reverse:

- The “Lo-reverse” clutches are worn out, there’s a broken sun shell, a fluid leak in the reverse apply circuit, or a worn boost valve.

- A high-viscosity additive/seal restorer may help with the fluid leak, and worn valve for the short term.

- Transmission must be removed and rebuilt.

Transmission won’t shift gears automatically (only by manual selection):

- Check the wiring and grounds.

- Check the function of the VSS and TPS (use code reader for this).

- Check the PCM for functionality and replace if necessary.

Step 2 – Check for gear upshift abnormalities

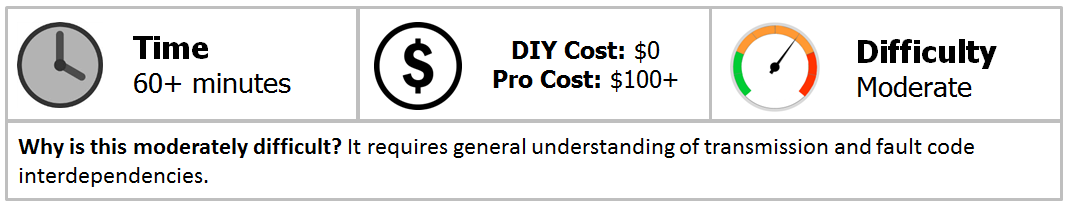

Many shift abnormalities involve the transmission shift controller’s numerous valving operations, which utilize accumulators, solenoids, pistons, and piston shafts. The valve body for the transmission is located underneath it, mounted just above and enclosed by its oil pan. It contains a complex, maze-like array of channels and shift control elements. And although it can be accessed from the bottom of the vehicle without having to remove the transmission, only the most experienced (or brave/foolhardy) should attempt any repairs within it.

The 1-2 shift doesn’t happen (the speedometer reads zero at all times):

- The transmission’s Vehicle Speed Sensor (VSS) should be checked.

- The VSS is located at the rear of the transmission, which has to be removed to access it.

The 1-2 shift occurs (but only when you let off the gas a bit):

- The Throttle Position Sensor (TPS) needs to be replaced (best case scenario).

- There’s a leak in the 2nd gear apply circuit (the servo assembly or 1-2 accumulator), resulting in a large drop in fluid pressure when the Powertrain Control Module (PCM) selects 2nd gear.

- Insufficient line pressure (worst case scenario).

The 1-2 shift is delayed and abnormal (i.e., accompanied with a shudder):

- The 1-2 accumulator piston is cracked or has jammed in its bore.

- The spring inside the accumulator housing is broken (and if the housing walls are scored, the housing needs to be replaced).

The 1-2 shift is delayed and harsh (plus Overdrive may not be available):

- The Throttle Position Sensor (TPS) should be checked.

- If the TPS’s electrical response isn’t smooth over its entire range of motion, the TPS needs to be replaced.

There’s a sudden grinding noise in 2nd gear (Reverse gear is also abnormal):

- The sun shell is fractured or its splines sheared off. Driving the car in this state will cause further damage.

- Transmission must be removed and rebuilt.

Step 3 – Check for missing gear selections

Only 1st and 3rd gears function (no 2nd, 4th, or Reverse gears):

- The sun shell is fractured or its splines sheared off. Driving the car in this state will cause further damage.

- Transmission must be removed and rebuilt.

No 3rd or 4th gear (can be driven in 2nd gear):

- 3-4 clutches are worn out.

- Transmission must be removed and rebuilt.

No 2nd or 4th gear (can be driven in 3rd gear):

- Servo seals are damaged or 2-4 band is worn out.

- Transmission must be removed and rebuilt.

No 1st or 4th gear (in Drive it shifts from 2nd to 3rd and locks the torque converter):

- Shift "A" solenoid has failed.

- Wiring problem from the PCM to the transmission.

No 1st or 4th gear (torque converter doesn’t lock, can be driven in 2nd, 3rd, and Reverse gear):

- Transmission is in “limp home” mode or lost electrical power.

- Check the under-hood fuse that powers the transmission. If it’s tripped, look for a short.

- If in “limp home” mode, look for PCM codes to trigger this fault condition.

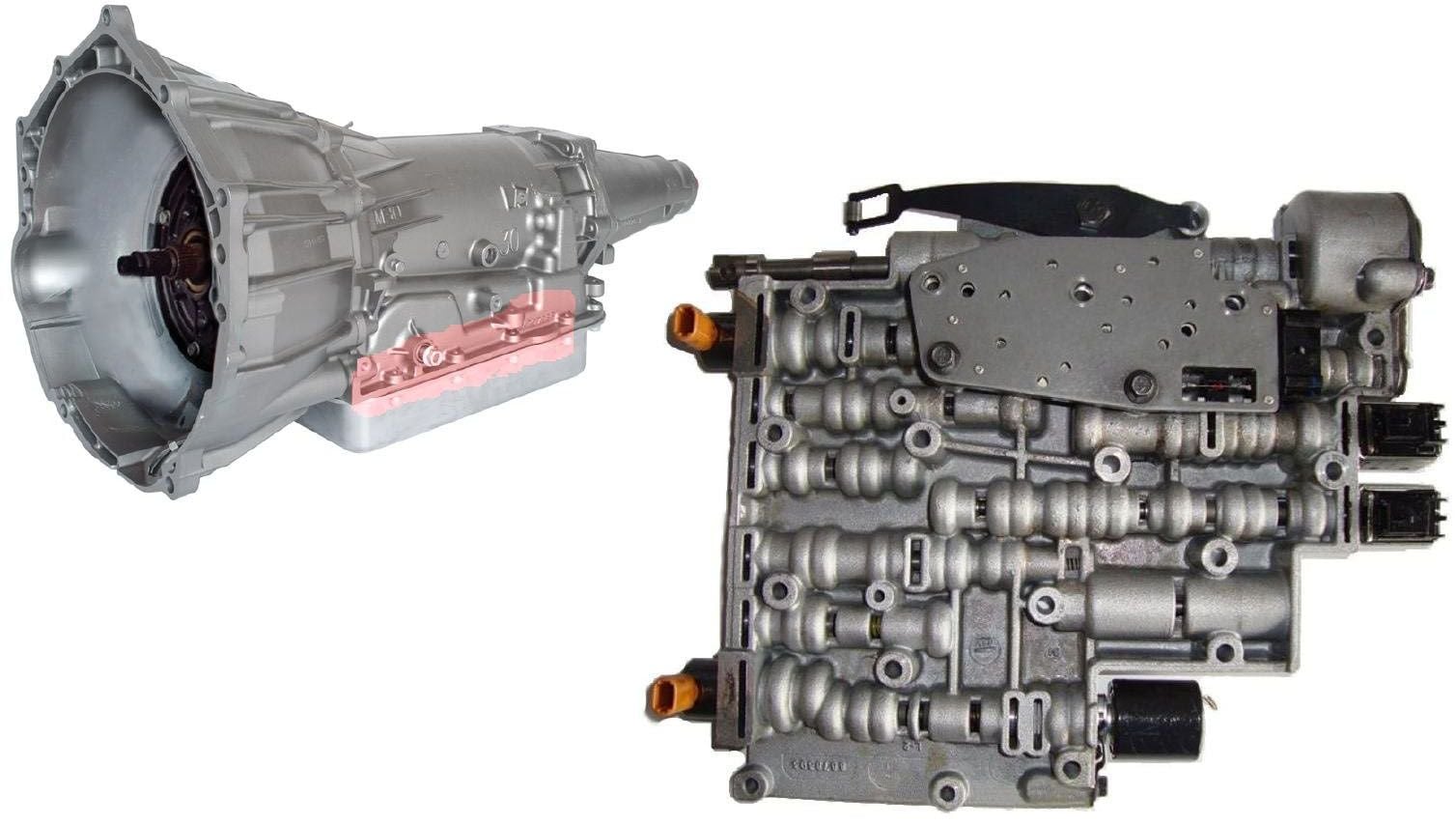

Figure 3. Torque converter and pump.

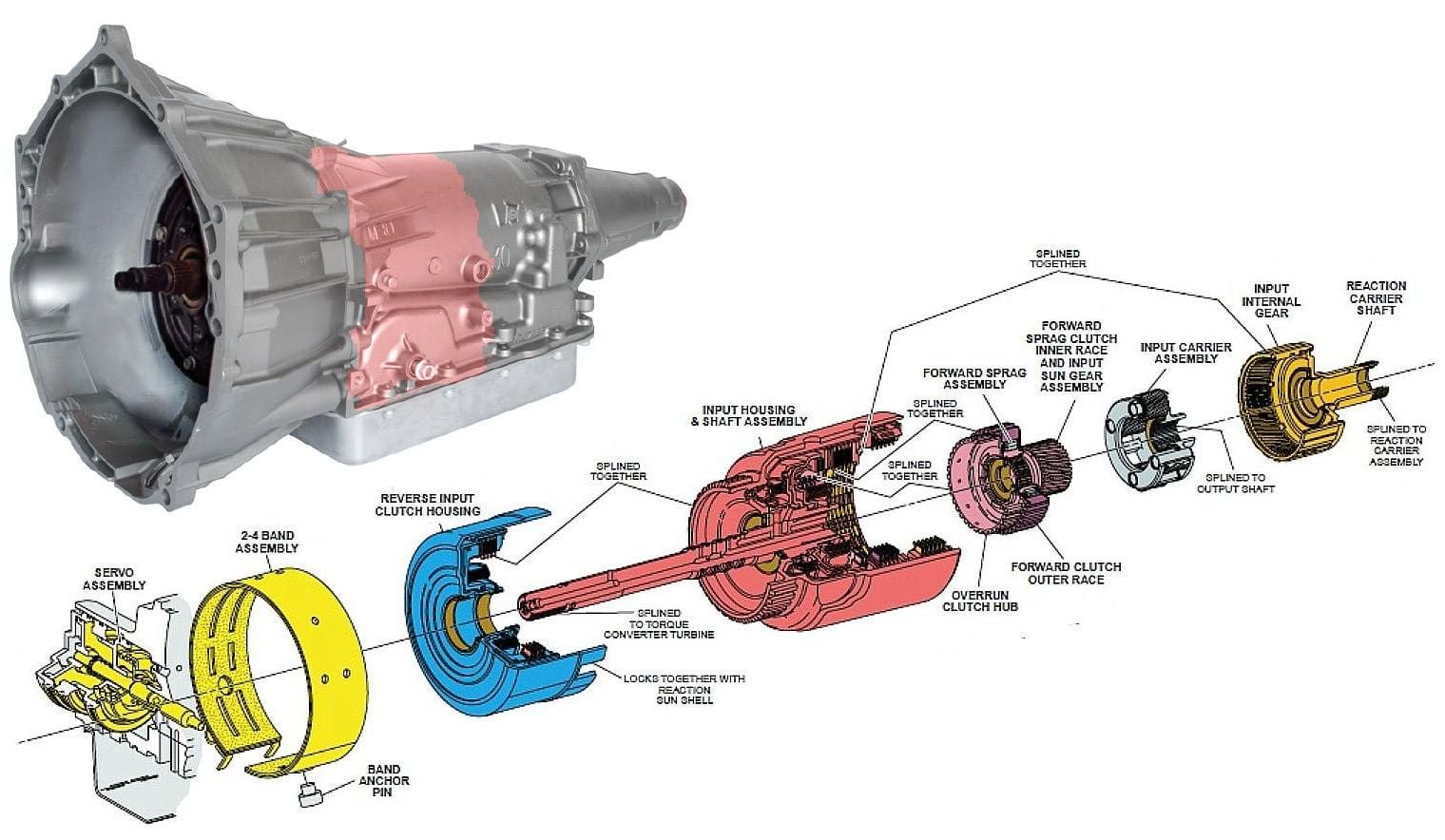

Figure 4. Reverse input, forward sprag assembly, and clutch.

Starts out in 4th (put in Drive it shifts from 3rd to 4th by itself and locks the torque converter; has to be manually shifted into 2nd to start moving):

- Shift B solenoid failure.

- Wiring problem from PCM to transmission.

Starts out in 3rd, other gears by manual selection only (but after turning the ignition on and then off, the truck runs normally):

- Even though the RPMs are high (or typically when this happens, too high), the VSS shows no movement.

- This indicates a VSS drop-off from a high stall torque converter (“stall,” indicating when the torque converter locks up under load).

- Reprogram the PCM to fix the VSS drop-off.

The 1-2 and 2-3 shifts are harsh (as is going from Park to Drive or Reverse):

- All gears are working and the problem may be intermittent.

- Check the Throttle Position Sensor (TPS) for a smooth electrical response, and replace as needed.

Step 4 – Check the torque converter operation

Located at the front of the transmission, the torque converter is situated inside the bell housing of the transmission. It is a fluid-filled coupling that acts as an intermediary between the engine and the transmission. When you set off from a stop and the engine revs shoot up a bit before the car takes off, that's the torque converter helping to convert initial engine revs into movement. When a torque converters wears, its vanes start to bend, which means that it cannot accurately control the movement of fluid inside the bell housing, causing erratic performance. An early sign of torque converter failure is having the engine revving higher than normal for shifts, which after the system warms up it returns to a more normal shift behavior.

Torque converter shudders in 4th while lockup is engaged (stops when the brake pedal is lightly pressed and the converter unlocks):

- Verify line pressure.

- Provided no valves in the Torque Converter Clutch (TCC) hydraulic circuit are worn, replace the torque converter.

Torque converter clutch doesn’t lock up:

- Brake pedal switches always on (switches need adjustment).

- TCC solenoid failure.

- TCC clutch worn out (replace the torque converter).

Torque converter clutch always locked up, causing harsh shifts, or excessive engine drag off the line:

- TCC solenoid circuit shorted to ground.

- TCC solenoid blockage.

- Torque converter failure, and you will need to replace the torque converter.

Related Discussions

- Silverado Transmission Problem - ChevroletForum.com

- 2500HD Transmission Problem - ChevroletForum.com

- Transmission Noise - ChevroletForum.com

- Won't Shift Out of Park - ChevroletForum.com

- Silverado Transmission - ChevroletForum.com